In a word... Energy.

Why Timber?

It is clear that we aren’t meeting the target for a 1.5°C global warming limit. This fact paired with the rapidly increasing demand for construction paints an ugly picture. Is there a way we can reverse the ongoing trend and create a more sustainable construction industry?

Energy Use in Construction.

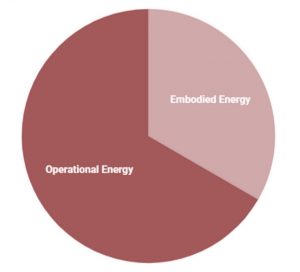

Energy use through the life of a building forms roughly a 2:1 ratio between operational energy and embodied energy, with the precise ratio depending on the project.

Construction as a carbon sink.

The building infrastructure we construct stands for many decades, and the sheer quantity of buildings we will need to produce between now and 2050 is a tremendous opportunity to trap carbon. Current construction methods privilege steel and concrete, which require massive quantities of energy and resources to produce. Traditional lightweight timber systems cannot match steel and concrete in meeting the demands that modern society has for its structures. Massive timber is the only material that is both renewable and can meet the demands that modern society has of its structures. Massive timber, AKA mass timber or engineered timber, is an umbrella term encompassing a range of value-added timber products created in a factory setting by recompositing solid-sawn timber boards into required shapes – unrestricted by the dimensions of boards sourced from any individual tree. The collaboration of mass timber construction, which sequesters up to 1 tonne of carbon per cubic metre of material, and high-performance building standards such as Passive House, presents a real possibility of true zero energy, decarbonised buildings.

The added value of Massive Timber

Beyond Environment

Scaling to the Future

Mass Timber and Prefabrication

So how exactly will we build a New York City’s worth of massive timber, high performance buildings per month for the next 40 years?

Prefabrication.

The strongest economic case for building with mass timber is how easily it can be prefabricated in controlled, offsite locations. Baked into its method of manufacture, individual boards, panels, beams and columns are composited to tight tolerances, cut to angle, fit with dowels, covered with insulation, fire protection, or finishes, and transported to site where they can be rapidly assembled into the final product. This change in building method challenges the current culture of construction: to be ready for manufacture, design must be completely resolved. This requires a high level of coordination between project teams, and a rigorous approach to building information modelling. We are witnessing a shift in the construction industry with the uptake of these methods, and a cultural shift that is heralding a future of highly efficient, prefabricated, sustainable and high performance buildings.

The way we handle our energy remains the foundation of our prosperity. It is clear that over the coming decades we will need to find ways of doing much, much more with much, much less. For the construction industry, this represents a grand opportunity to reinvent our infrastructure and scale to the future. By harnessing prefabrication, applying low embodied energy materials, and designing for low operational demand, we can build beautiful, net-zero energy buildings as the platform for our civilisation to thrive.

That is why we choose to design in timber.

- https://climateanalytics.org/latest/australia-on-track-to-become-one-of-the-worlds-major-climate-polluters/

- https://thebulletin.org/2019/01/global-warming-of-oceans-equivalent-to-an-atomic-bomb-per-second/

- Department of the Environment and Energy (2019) Australian Energy Statistics, Table C

- https://www.worldgbc.org/sites/default/files/UNEP%20188_GABC_en%20%28web%29.pdf

- https://www.ipcc.ch/sr15/

- https://www.asbec.asn.au/wordpress/wp-content/uploads/2018/03/180208-ASBEC-CWA-The-Bottom-Line-household-impacts.pdf

- https://passipedia.org/basics/what_is_a_passive_house

- https://architecture2030.org/new-buildings-embodied/

- https://open.library.ubc.ca/cIRcle/collections/ubctheses/24/items/1.0071305